Inventory control and accuracy has been a high priority of Snyder’s since first installing a computerized inventory system in 1993. It was discovered early on in dealing some computerized yards that the salesmen who worked at these yards often times did not trust their own inventory.

Snyder’s owners and employees decided that they were at an advantage since

they would be starting from scratch adding inventory into the computer. With a goal of 100% accuracy in mind, Dan and Andy Snyder have created a system that has many checks and rechecks built into it. It was clearly understood that computers do not make mistakes, but humans do, so it was the focus of our system that these checks and rechecks would look for the mistakes made by normal humans.

The inventory process at Snyder’s begins soon after the arrival of the salvaged vehicle. Dan Snyder

inventories all vehicles using a preprinted inventory sheet generated by the Hollander Yard Management System. There

is the possibility of inventorying 105 separate pieces on each vehicle. The preprinted inventory sheet has an outline based on

a listing of all options available for each of the 105 parts. This outline-based listing allows easy viewing and easy selection of the correct option used on that particular vehicle.

Each sheet metal part is wiped off with a rag to remove loose road debris and to bring out more gloss and reflection. These parts are then looked at very closely from an angle paying particular attention to reflections on the paint. This is the best way to spot any minor imperfections in the sheet metal part. The imperfections are described in detail and assigned a damage amount. The damage amount is the amount of time necessary to “clean up” or repair the imperfection in a body shop and restore the part to its like new, pre-paint condition. The following are the general rules used to determine “cleanup” time at Snyder’s.

Cleanup time guidelines:

- 1 door ding = 1/2 hour cleanup

- 2-3 door dings = 1 hour cleanup

- Credit card to palm size dents = 1 hour cleanup

For large dents simply add the number of palms it takes to cover the damaged area and this will give the number of total hours to repair the damage.

Using the guidelines listed above and paying very close attention to minor damage that most yards “overlook”, Snyder’s has developed an excellent reputation with the Insurance Industry as well as the professional body shops that they have served.

Mechanical parts are also subject to scrutiny when going through the inventory process. It is common practice to not inventory suspension parts that are at the point of impact on a vehicle that has been wrecked. Many times when a vehicle is inventoried initially it is very difficult or impossible to fully inspect mechanical parts. For this reason a unique step was added to the inventory process.

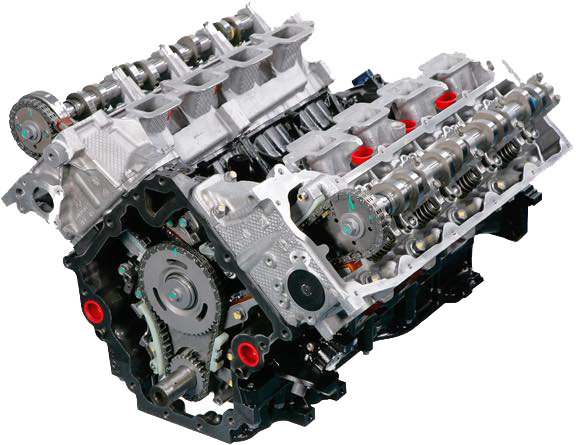

The inventory process and the dismantling process merge when the vehicle is moved into the dismantling facility. At this point the dismantler has the inventory sheet which he uses for instructions in the dismantling process. The dismanteler also takes advantage of this opportunity to check for mistakes made by the original inventory person, as well as check the condition of “hidden” parts. Checking the condition of these hidden parts is facilitated by vehicle lifts and tools not available at the time of the original inventory. Many other questions can be answered at this time as well. Things such as the amount of amperage an alternator puts out cannot be accurately determined at the time of the initial inventory. The dismantler also will start and run each vehicle until it at normal operating temperature. A compression reading is taken on each cylinder and the high and low readings are noted. At this time the spark plugs are inspected for any signs of oil usage. Listening to the engine, checking compression and inspecting the spark plugs give a very good overall impression of the actual condition of the engine. All this information is recorded for further use by the salesman when representing the engine to the potential customer. Transmissions are inspected at this time as well. Automatic transmissions are put into Drive and Reverse to ensure that they will go into both gears. If the vehicle has over 100,000 miles on it, the fluid pan will be removed and the unit will be inspected for any metal shavings or an inordinate amount of clutch material, which may have accumulated in the pan. If it is possible, manual transmissions will be put into each gear and the clutch released to listen for worn gears or bearings.

After the vehicle is totally dismantled and before it leaves the dismantling building the entire vehicle is re-inventoried piece by piece to ensure the accuracy of the original inventory as well as update information on hidden parts. At this point, some parts are even deleted after being found to be of inferior quality or possibly damaged in the dismantling process itself. All of this extra effort is put forward in an attempt to have an accurate description of the part in the computer and ultimately to provide a quality used part to the consumer as it was described by the salesperson.

Inventory accuracy is also enhanced by the data entry person. At the time of entry into the computer, the data entry person enters the information, line by line, from the printed inventory sheet into the computer data banks. At each keystroke, the inventory is double-checked for accuracy by the clerk. Mistakes made by the original inventory person are often found at this point and corrected before impacting the integrity of the inventory accuracy.

Inventory accuracy does not end when the dismantled vehicle is moved to the yard. On the contrary, the inventory is constantly changed and updated as the vehicle ages in the yard. Any inventory change that may occur due to parts sales or accidental damage incurred in the yard is noted on the pull slip by the part puller. These changes are then corrected at the end of each day by the individual salesman that created the pull slip initially.

The latest addition done at Snyder’s in an effort to reduce inventory problems was the creation of a new position. A Yard Foreman position was created and staffed by the most senior yardman. This person’s responsibilities include inspecting the part for condition before it is pulled, inspecting the job site after the pull is finished, and following through to be sure the part has been placed in the correct location with the correct stock number and the salesperson’s initials. If inventory accuracy has been compromised at any of these steps it is the Yard Foreman’s responsibility to bring the information to the attention of the sales staff for corrections in the computer.

As you can probably guess, not all automotive recycling facilities go through this much trouble to keep their inventory accurate. These extra steps cost money. Snyder’s feels that this money is well spent and that it actually will return to them many times over in satisfied customers and a professional reputation that will follow them into the coming years.